HANANO SURFACE®

HAnano Surface is a registered trademark of Promimic AB, Mölndal, Sweden

EXCELERATE

HAnano Surface® combines several properties, known to improve osseointegration, in one unique surface modification. 4

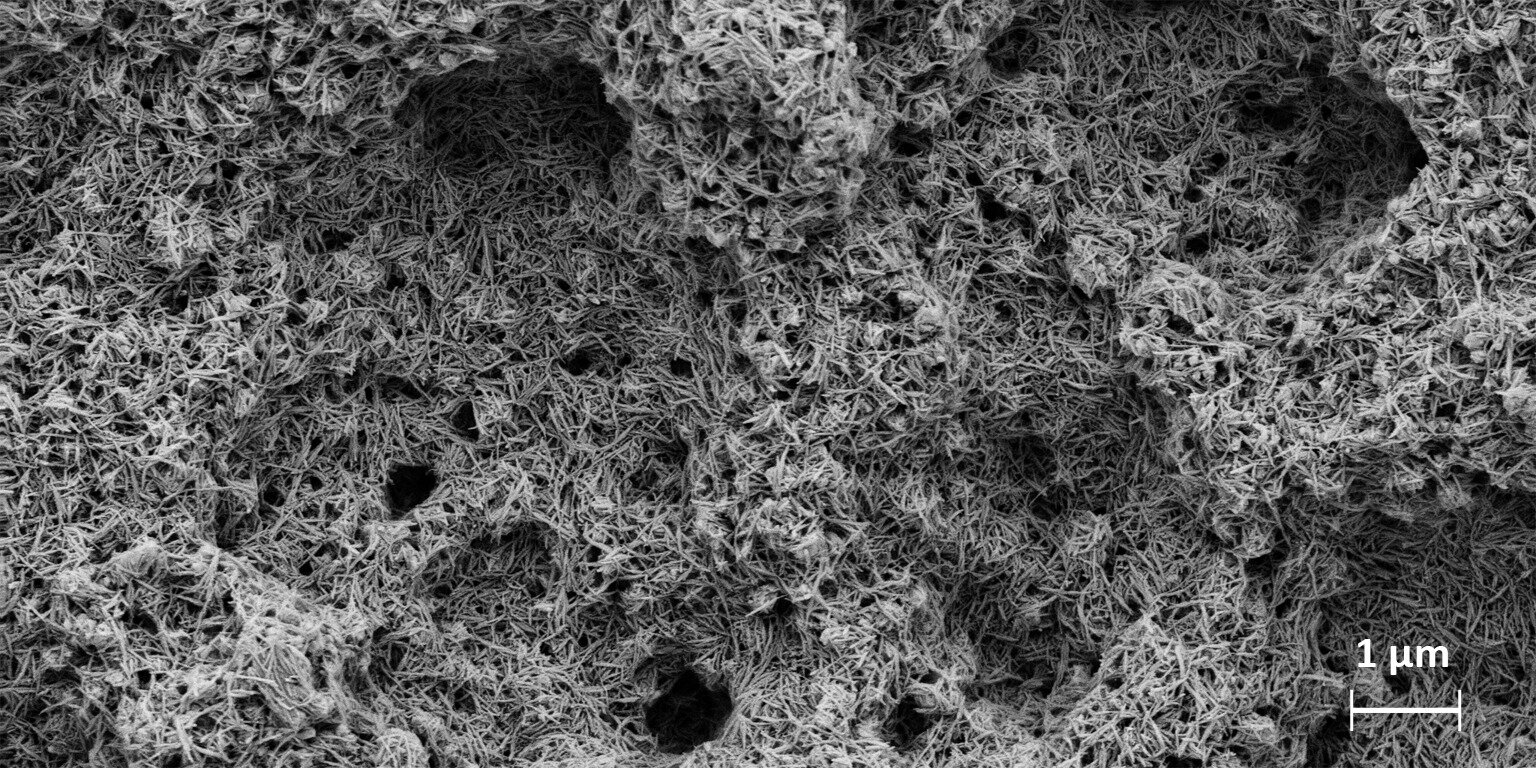

HAnano Surface® is a 20 nanometer thin implant surface modification composed of crystalline hydroxyapatite (HA) particles that through shape, composition, and structure mimic human bone tissue. HAnano Surface® is used clinically and has proven to significantly accelerate and enhance osseointegration of implants.*

REFERENCES

HAnano Surface is a registered trademark of Promimic AB, Mölndal, Sweden

4 https://www.promimic.com/products-and-technology/

*osseointegration of human dental implants

Promote Bony Ongrowth

Significantly accelerate and enhance integration of implants using nano-sized crystalline hydroxyapatite particles*

Hydrophilic properties improve adsorption of blood and extracellular fluids, promoting an osteoconductive integration process

Enables newly-formed bone to grow directly into the micrometer topography (roughness) of the implant surface

In laboratory studies using animals, HAnano showed early bone formation and improved implant anchoring*

REFERENCES

Meirelles L (2008), ‘The effect of Chemical and Nanotopographical Modification on the early stages of osseointegration’

Jimbo R (2011), ‘Histological and three-dimensional evaluation of osseointegration’

Jimbo R (2012), ‘Nano hydroxyapatite-coated implants improve bone nanomechanical properties’.

*in laboratory studies using animals

Wettability/Hydrophilicity

AxTiHA Integrated with HAnano Surface® *real time

HAnano Surface® Remains Hydrophilic Over Time

Acid etched titanium implants were lowered into dyed water (down to a predetermined length).

Evaluation of liquid absorption after 0, 1, 4, 8 and 12 weeks of storing in glass vials with a Teflon gasket.

Results

HAnano Surface® coated implants remain hydrophilic over time.

Heat treated implants become more hydrophobic over time.

Technology and Process

Application of HA Liquid

In the first step, the coating liquid is applied to the implant.

Thin Film Formation

In the second step, excess coating liquid is removed forming a thin film.

Heat Treatment

The final step involves a short heat treatment